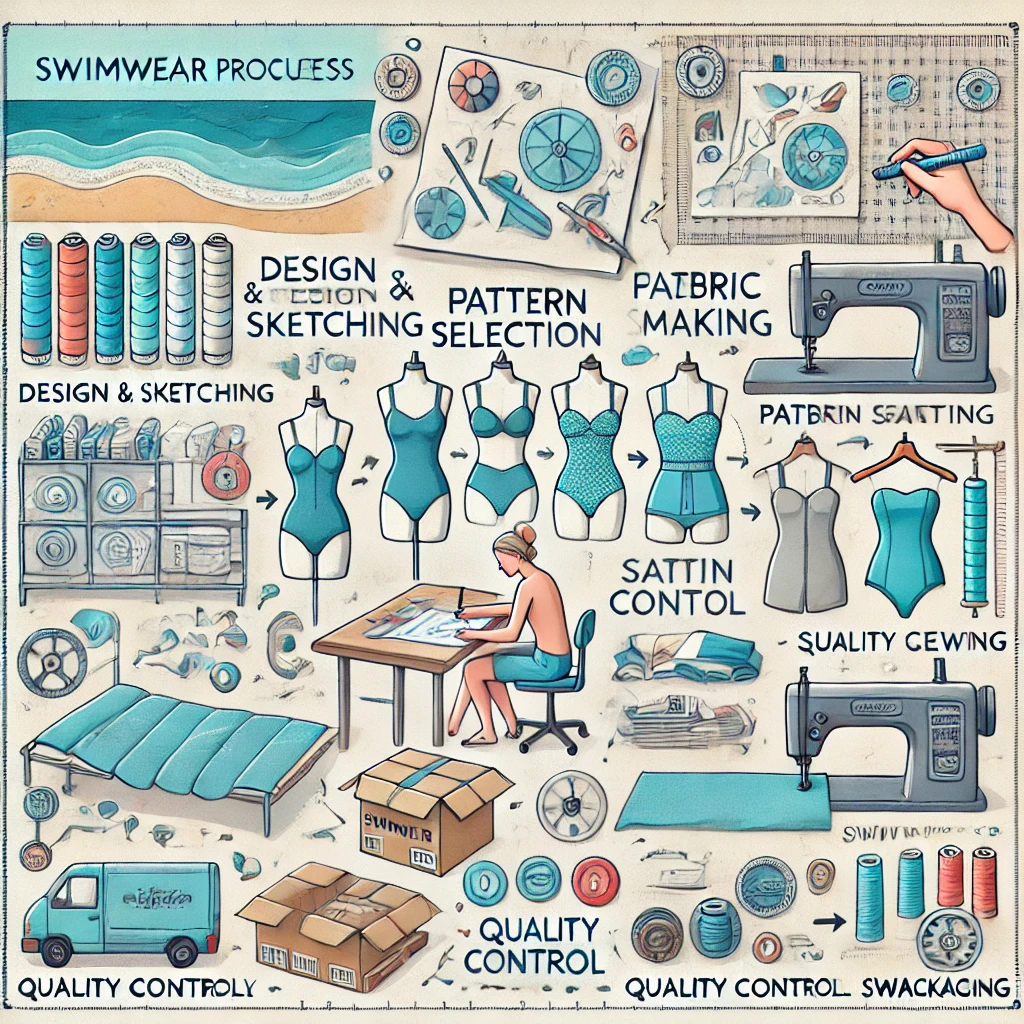

Ready to make waves with a swimwear brand? Understanding the production process is key. Swimwear has unique fit requirements, fabric needs, and seasonal demand, which requires thoughtful planning and understanding of how production works. If you’re considering starting a swimwear brand, here’s what you need to know to navigate the swimwear production process like a pro.

1. Understand Your Product & Market

Before you can start the manufacturing process, you need to have a clear understanding of what you’re designing and who you’re designing for. Understanding your product and market makes communication with manufacturers smoother and also allows you to serve your target customers better as well.

- Do Your Research: With any fashion business, it’s essential to make sure your designs will be commercially viable. You’ll need to research the swimwear market, look at seasonal trends and forecast reports, and analyze best-selling styles to understand what’s resonating with your target audience. Also pay attention to customer demands from your competitors to see how you may be able to incorporate them into your designs.

- Define Your Brand Values: Every step of the production process is an opportunity to align your brand with your values. Whether it’s promoting sustainability, inclusive sizing, high quality, or women’s empowerment, these values can shape your brand’s reputation and customer trust. For example, as a woman-owned swimwear brand, this could mean prioritizing designs that support and flatter women’s bodies or working with factories that empower female workers.

- Design With Your Customer In Mind: With little fabric to work with in swimwear, you must be strategic and consider the specific needs for designing for your target customers. For example, if you design women’s swimwear, you must understand how to achieve flattering silhouettes that accommodate curves in all shapes and sizes. This means you may want to consider how you can offer a more customizable fit to your customers with options like adjustable straps, removable padding, or multi-way tie swim options. Once you’ve done your research, combine your knowledge and inspiration into moodboards, sketches or tech packs to communicate your vision to your manufacturer.

- Pick the Right Fabrics: Fabric sourcing is important in ensuring your designs are both fashionable and functional. Swimwear fabrics must be durable, stretchy, and quick-drying. Common choices include nylon-spandex blends, but as sustainability becomes more important, many designers are considering eco-friendly swimwear fabric options like recycled polyesters. If you’re not sure where to start with fabric sourcing, you can order fabric samples online, or attend trade shows.

2. Find the Right Manufacturer

Choosing the right manufacturing partner is one of the most important decisions you’ll make, so make sure you choose wisely. There’s many factors to consider, such as their expertise in swimwear, production costs and timelines. Finding a manufacturer who can execute your vision and brand needs is key to long-term success.

- Use Trusted Sources: Finding the right manufacturer can feel overwhelming, but manufacturing sourcing platforms can simplify the process by connecting you with vetted, reliable options. Search for manufacturers with a specialty in swimwear production and ask for samples of their work and details on their processes and timelines.

- Ask the Right Questions: It’s important to interview your manufacturer to ensure they can not only accommodate your design needs, but operational and financial needs as well. Some questions you should ask your potential manufacturer include:

- What is the minimum order quantity (MOQ)? Are there small-batch options?

- What is the sampling process like?

- Are there sustainable fabric options?

- What is the lead time for production?

- Consider the Country of Production: The “made in” label on your swimwear is more important than you think, and not just for customer perception. Domestic manufacturers may be able to offer faster production times and easy communication, but often at a higher price point. International manufacturers can be more cost-effective but require additional time for shipping and quality control. You’ll need to decide if local or international manufacturing will better serve your needs, budget and operations.

- Implement Legal Protection: Establish a clear, comprehensive contract with your manufacturer outlining how issues such as missing or damaged items will be handled, along with repercussions for delays or quality concerns. Having these terms in writing protects your business and ensures accountability throughout the production process.

3. Sampling & Quality Control: Test, Refine, Perfect & Check

Product sampling is essential to ensure your designs look, feel and fit their best on real bodies, which will help reduce returns and poor reviews. Never skip this step! It’s very important to be proactive rather than reactive, so taking the extra time for quality control in the early stages of production will pay off in the long run.

- Inspect To Perfect: Your first sample (or two) won’t be perfect, and that’s okay. Use your samples to spot design or stitching flaws and refine details. Refer back to your moodboard, sketches and tech packs to be able to communicate your revisions clearly with the manufacturer and adjust patterns as needed.

- Conduct Fit Testing: If possible, have a range of fit models with different measurements and body types try on your samples to make sure your designs fit well on different body shapes and sizes. Fit testing also provides a great opportunity to see where you can add more customizable or supportive features into your swimwear like underwire, adjustable clasps, etc.

- Fabric Testing: You’ll need to not only review the design and fit of your sample, but the fabric quality as well. Be prepared to test your swimwear fabric for stretch recovery, durability, and opaqueness when wet. It will keep its color after being exposed to sun, chlorine and the washing machine.

- Inspect Your Production Run: Quality control doesn’t stop at sampling! Once your bulk order arrives, be sure to check each piece for stitching quality, fabric integrity, and consistency across sizes. A reliable manufacturer will have their own quality control process, but it’s important to double-check internally as well. If you encounter any imperfections in your products, be sure to speak up right away to resolve with your manufacturer.

4. Plan for Production Times and Seasonal Deadlines

The swimwear industry is seasonal, with demand peaking in spring and summer, so plan your production schedule accordingly. You’ll want to maintain tight deadlines in the winter months to ensure you’re set up for a profitable summer season.

- Plan Ahead: Give yourself enough buffer time to handle delays. If you want to launch a summer collection, start working with your manufacturer at least 6–9 months in advance to factor in time for sampling, revisions, and shipping.

- Anticipate Restocks: Restocking a bulk order or restock can take anywhere from 6–12 weeks. While a sold-out item on your website may boost the perception of demand, denying customers the instant gratification of buying when they’re ready could end up costing you—literally. Be proactive and order restocks as your inventory starts to sell.

- Stay Organized: Keep track of your production timeline, inventory needs, and delivery schedules using project management tools or spreadsheets. It’s important to keep track of delivery cutoff dates, holidays, and seasons with higher lead times.

5. Budget for Production Costs

The most important thing you can do when starting a swimwear line is make sure you are financially prepared for the production process. Even in small batch production, swimwear production can be expensive, so budgeting is crucial. You’ll need to understand your final production costs after fabric sourcing, sampling, production and shipping. Understanding your costs upfront will save you from surprises and help you price your products for profitability.

-

- Understand Production Fees

- Sampling & Revision Fees: Most manufacturers charge for samples, which can add up as you refine your designs. Be prepared to budget for additional tweaks, pattern change fees, and ordering samples in additional sizes.

- Material Sourcing: Costs to consider when fabric sourcing include price per yard, custom printing or dyeing, shipping costs, and third-party sourcing services if your manufacturer doesn’t provide it. You’ll also need to consider how MOQs can affect your budget and costs for specialty or sustainable fabrics that may come at a premium price.

- Shipping & Customs: Whether you manufacture domestically or internationally, you’ll need to have your products delivered to their place of fulfillment, so consider shipping costs from the manufacturer to you. If you’re working with overseas manufacturers, you’ll also need to factor in duties and customs fees.

- Understand Production Fees

- Price for Profitability: Once you understand your true cost per item, you will have a better understanding of how to price your product. Budgeting for hidden costs allows you to set your wholesale and DTC prices to ensure that you’re not just breaking even but making a profit on your swimwear.

Final Thoughts

Navigating the swimwear production process may feel overwhelming at first, but with the right preparation and partners, you can set yourself up to make waves in the swimwear market. By mastering the production process and making informed decisions, you’ll be one step closer to launching a successful swimwear brand.