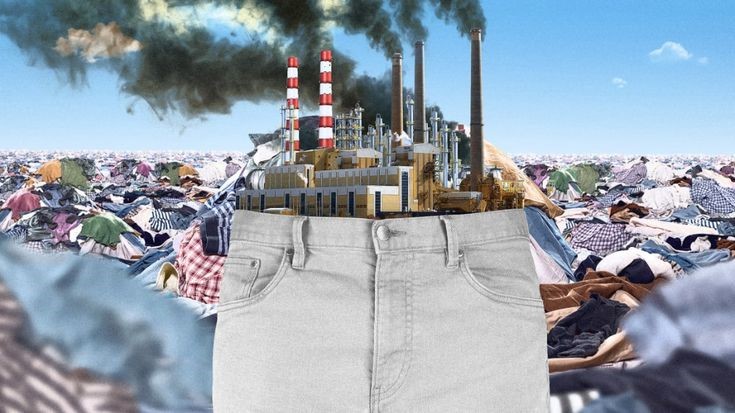

Innovations and technology have been a boon to mankind. With the Industrial Revolution, it brought a new phase and introduced industrialisation for helping and making people’s work easy and efficient. Anything excessive is not good for the environment. Because the rise in industries and factories has led to an increase in pollution levels. Fashion that started as a necessity and representation of art is no longer limited. Due to overproduction of waste and fuel emissions caused by apparel factories, it is a concerning fact all over the world. Environmental forums have started various regulations and rules for the carbon footprint reduction process. And there are various steps that can be taken to achieve this concerning situation through sustainable practices.

image credit: pinterest

Carbon Footprint And Its Impact Due To Apparel Practices

The concept of carbon footprint is about the amount of greenhouse gas emissions caused directly or indirectly by factories or organizations during the production process. Greenhouse gases are usually carbon dioxide emitted through factories. There are direct and indirect emissions of greenhouse gases. Direct emissions are the use of fuels being used for transportation processes for the delivery of products. Indirect emissions are those produced during the production process or manufacturing waste. Both have a negative environmental impact due to avoiding green practices in fashion.

The apparel industry contributes to producing carbon emissions and is increasing carbon footprints in several ways:

→ Raw Materials Production And Manufacturing Process

When fibers like cotton or other natural fibers are produced, it uses a lot of chemicals as fertilizers and water consumption to be grown. Those chemical fertilizers, along with water, are dangerous when being released in water bodies, thus increasing carbon footprint. Other fibers, like polyster, when produced also release greenhouse gases. The process involved in the production of textiles requires fuels, and techniques like dyeing too involve the use of fossil fuels, thus creating a negative environmental impact.

image credit: pinterest

→ Transportation And Disposal

After the production process is completed, the apparel is packed and shipped for delivery all over the world. This requires vehicles for transporting the parcels or sourcing of raw materials. This continues along the chain, thus emitting carbon dioxide and other harmful gases. And when the clothes are disposed of, due to an unsure disposal process, most of the time they end up in landfills or get dumped. This releases methane into the environment when decomposition takes place.

Top 5 apparel practices for reducing carbon footprint

1. Use of Renewable Sources & Green Energy

Factories can adapt energy-efficient machines and methods for apparel production and techniques that help in reducing carbon footprint. Greenhouse practices in fashion can be implemented with the use of renewable sources of energy and green house energy for producing clothes. It can invest in machines that support renewable sources of energy, such as wind, solar, or hydroelectric. And maintain this sustainable practice regularly for getting a positive response. This changes energy consumption ways and its dependency on fuels and other nonrenewable resources.

image credit: pinterest

2. Using Alternative Materials

Factories can find alternative materials for reducing carbon footprints through apparel manufacturing. They should source more sustainable materials for usage. This reduces harmful environmental impact. Which is mostly caused by the use of materials that contribute to an increase in carbon footprint. As the materials or fibers, when produced, used a lot of chemical fertilizers. Thus, use of organic and recycled materials brings drastic changes and helps in carbon footprint reduction.

3. Water Management Techniques

Due to technology and innovations, it has been able to produce various water management techniques for reducing water wastage in apparel factories and thus following green practices in fashion. Factories can use water consumption methods such as closed-loop water systems or air dyeing methods. This used no or very little consumption of water in the production process. They can apply techniques that help to reuse water for other production stages and are sustainable practices. Thus, it helps in reducing freshwater consumption and the release of carbonated water in rivers and lakes, thus reducing carbon footprint.

image credit: pinterest

4. Waste Reduction Methods

Zero waste management is an effective approach that can help in reducing carbon footprint. This can be adapted while pursuing a circular fashion economy. The approach is known for reducing waste caused by apparel production and maintaining to use the fabrics and other materials in the production loop to the fullest and practice such sustainable practices. This helps them in proper waste management and prevents them from emitting greenhouse gases, thus creating a positive environmental impact. It motivates about reuse, recycling, and upcycling of apparel products.

5. Transparency

Factories need to optimize their supply chain for reducing their carbon footprint. As it includes important production factors such as transportation and sourcing of raw materials and other resources. It should be clarified by the manufacturer to suppliers about sustainability. It is important for them to be on the same page and be responsible about the environment. They should collaborate with suppliers that are serious about sustainable approaches and green practices in fashion. Factories should make them aware of the concept and motivate them to follow this practice and achieve carbon footprint reduction. They should also invest in vehicles that consume less fuel or work on green energy.

image credit: pinterest

How Does Maker’s Row Help to Adapt Such Practices?

It is important and responsible behaviour from brands and factories to adapt new practices. Maker’s Row is a platform that gives you informative insights for the production process. With the help of manufacturers and factories that connect to the brands according to the vision and ideas, they help in attaining a successful production process. Even if a brand is not able to create a path, there is advice and knowledgeable guidance available for brands to get them from industry experts and make you create an appropriate way for a successful future.

Conclusion

Factories and industries have opportunities for contributing through sustainable and green practices in fashion. Reducing carbon footprints is a practice that is being adapted by many factories and organizations. But apparel factories have some practical solutions and technology that hardly go wrong or are ineffective. With a few simple steps and a sense of responsibility with conscious decision-making. Factories can surely achieve this useful practice of sustainability and reducing carbon footprint and create a better environmental impact.

You Can Read More..