Sustainable manufacturing technology is no longer a buzzword but is considered a necessity in all of today’s clothing industry. Picture the factory where everything—from fabric cutting to stitching—is surveyed and guided by AI systems, while automated machines do the teachers to the intricate designs with their utmost best. Some of the companies like Adidas and Zara really embrace digital transformation in the fashion industry and engage in AI in garment production for the purpose of revolutionizing their supply chains. But truly, how do these technologies change the way production is rendered efficient and wasteful, and how can it really be felt in terms of sustainability?

In this blog page, we’ll explore how technology in clothing manufacturing and smart manufacturing in fashion are shaping the future of apparel production.

The Rise of Smart Manufacturing in Fashion

Smart manufacturing in fashion brings data together with automation and real-time monitoring systems. From now on, factories will also have the capacity to take advantage of IoT in textile manufacturing for better workflows at lower error levels.

Key Benefits of Smart Manufacturing:

- Real-time data monitoring

- Increased production speed

- Reduced material waste

For example, brands like Zara use technology in clothing manufacturing to forecast demand and prevent overproduction.

The Role of AI in Garment Production

AI in garment production helps optimize fabric cutting, predict fashion trends, and improve inventory management. AI-powered tools can analyze customer preferences and suggest design adjustments.

Case Study: Stitch Fix uses AI algorithms to curate personalized clothing recommendations, reducing excess inventory.

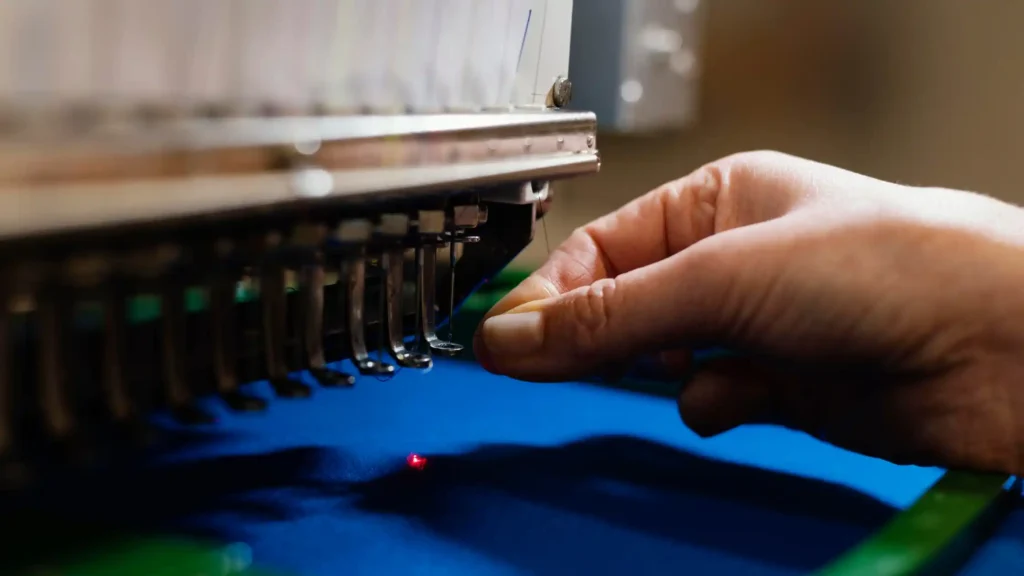

Automation in Clothing Production

Automation in clothing production involves using robots and automated machinery for tasks like stitching, dyeing, and packing. This is basically a means to reduce manual reliance and ensure accuracy in tasks that would otherwise depend on manual effort.

Benefits of Automation:

- Faster production cycles

- Higher accuracy

- Lower operational costs

For example, Adidas applies this technology for more than just automated customization to manufacture customized sneakers within hours.

Innovations in Clothing Manufacturing Technology

The top 3D printing technologies in fashion manufacturing, along with Advanced garment production technologies, allow the manufacturers to prototype designs faster. The amount of waste is minimized using this technology, and time for production is reduced.

How 3D Printing is Used in Fashion:

- Prototyping complex designs

- Custom-fit garments

- Sustainable material usage

How Maker’s Row Enables Technology to Clothing Manufacturing

Maker’s Row operates well in connecting those very businesses with manufacturers, emphasizing sustainable manufacturing technology, AI in garment production, and digital transformation in the fashion industry. It makes it easier to find all these reliable partners using high-tech garment production and smart manufacturing in fashion.

How Maker’s Row Helps:

- Access to a network of verified manufacturers;

- Streamlined communication tools for seamless collaboration;

- Insights into the latest technology in clothing manufacturing.

Today, most modern manufacturers on Maker’s Row use IoT in textile manufacturing and automation in clothing production for their most efficient operation. From startup to established brand, Maker’s Row will help you find partners who will suit your technology and sustainability goals.

The Digital Transformation in Fashion Industry

The digital transformation in the fashion industry streamlines supply chains, improves inventory accuracy, and supports real-time tracking. Platforms like PLM (Product Lifecycle Management) tools help brands manage design, production, and distribution seamlessly.

Example:

Brands like H&M use digital systems to manage global supply chains efficiently.

Sustainable Manufacturing Technology: A Necessity

Sustainable manufacturing technology ensures that environmental impact is minimized. Factories are adopting energy-efficient systems and recycling waste materials.

Sustainable Practices in Modern Apparel Production:

- Use of recycled fabrics

- Energy-efficient production systems

- Waterless dyeing technology

Technology and the Future of Clothing Manufacturing

The integration of IoT in textile manufacturing, AI in garment production, and digital transformation in the fashion industry will continue to drive innovation. Future factories will focus on reducing waste, improving efficiency, and meeting sustainability goals.

Final Thoughts:

The adoption of sustainable manufacturing technology and technology in clothing manufacturing is no longer optional; having technology in sustainable manufacturing and AI in garments has indeed become almost necessary for brands wishing to compete in a market. These technologies bring increased efficiencies, less waste, and the last but not least importance—an environmentally responsible fashion industry. Platforms such as Maker’s Row serve as a bridge between businesses and technology-driven manufacturers, facilitating easier adaptation to this dynamic landscape. By embracing innovation, the fashion industry can pave the way for a smarter, greener, and more sustainable future.

Looking for more insights? Check these out!