In the past few years We’ve seen a major shift towards sustainability in the fashion industry, making Lyocell the preeminent eco-friendly clothing line. So what is Lyocell? Organic pulp from wood is used to make this rich substance. It feels soft and is extremely breathable. With a unique closed-loop production process Lyocell is unique in that it has a lower environmental impact compared to traditional fabrics such as cotton and viscose. Join us as we explore the amazing properties of lyocell. Its benefits Why choose to use sustainable fashion? And let us explore how it happened.

What is Lyocell?

Lyocell is a type of fiber made from wood pulp. Commonly obtained from trees such as eucalyptus, beech and oak, the combination of durability and high performance makes this fabric popular. Its smooth surface and breathable nature have made it a favorite among designers and consumers looking for alternatives to traditional materials.

But what makes Lyocell unique? In contrast to other textiles, Lyocell is made by a closed-loop procedure. This indicates that nearly all of the solvents and water used in manufacturing are recycled and utilized again. Therefore, it reduces the environmental impact compared to traditional fabric production. This is the reason why many People view Lyocell material as a sustainable option for clothing, home textiles and more.

How is Lyocell Made?

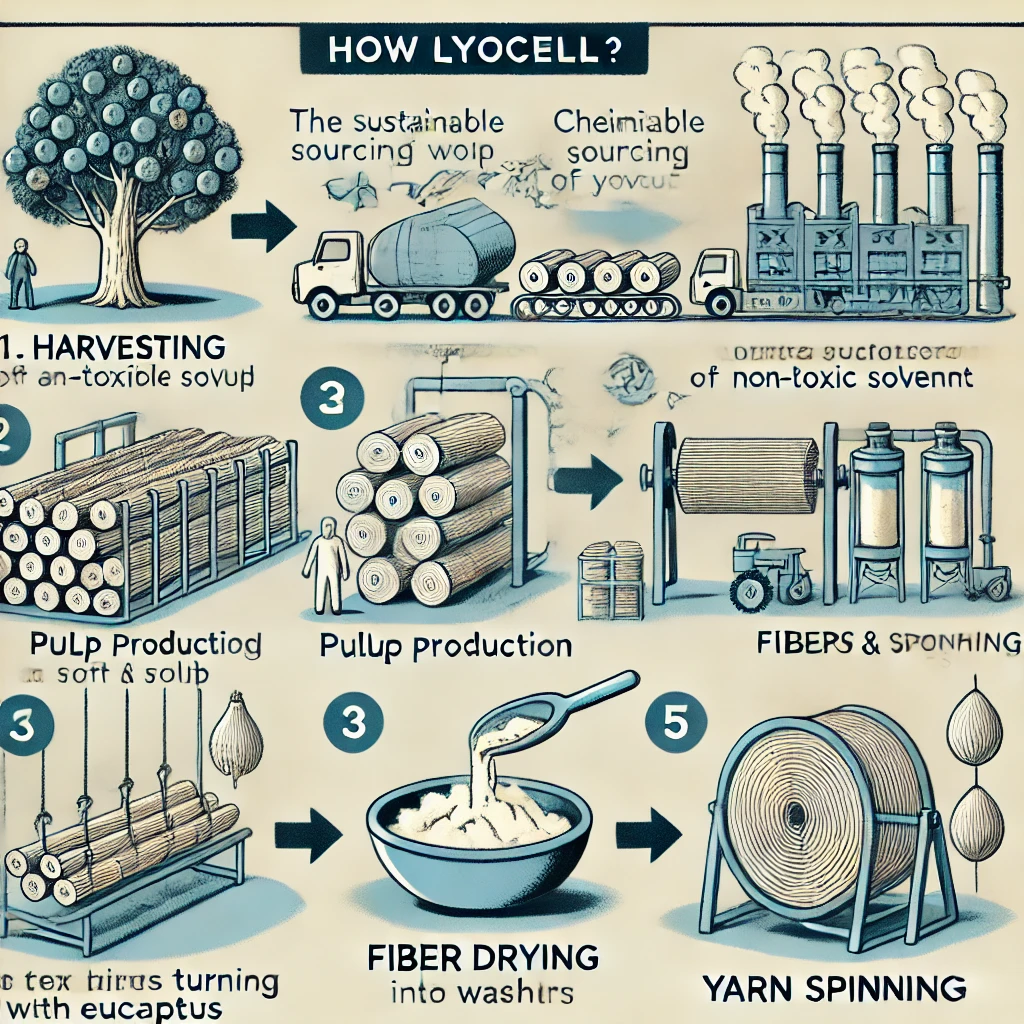

What really differentiates lyocell from other fabrics is the way it is produced. Here’s a deeper look at the making process for this amazing fabric:

- Harvesting the Wood Pulp: First, wood that has been collected responsibly is used in the process; this wood is usually from trees that grow quickly, such as eucalyptus. Wood pulp made from this wood is used to create lyocell fibers.

- Dissolving the Pulp: An organic solution that is safe to use is used to dissolve the wood pulp. This is a crucial phase in the closed-loop process which allows lyocell manufacturing to be less harmful to the environment than traditional methods such as those applied to silk.

- Spinning the Fibers: The final mixture is then forced through spinning wheels to produce lyocell fibers with a fine texture. Before being turned into yarn, these fibers are cleaned and dried.

- Creating the Fabric: Lyocell yarn is woven or woven into fabric. This creates a smooth, durable, and customizable material. Suitable for use in clothing. home textile and other uses.

The higher-quality fabric created by this method has become known for its strength, softness, and ability to drain away moisture. It is also less harmful to the environment.

Where Do They Make Lyocell Fabric?

The main production locations for lyocell fabric are a number of areas renowned for their capacity to make textiles, including:

1.Austria: Under the TENCELTM brand, the Austrian business Lenzing AG is a top manufacturer of Lyocell. One of the most well-known brands linked to superior Lyocell production is Lenzing, which is renowned for its inventive and sustainable methods.

2.China: Lyocell is produced in large quantities in China, a major center for textile production. Lyocell is supplied by numerous companies and manufacturers nationwide for a range of applications, including home textiles and clothing.

3.India: With several textile manufacturers and mills using the fabric in their products, India is another major producer of Lyocell. In keeping with its reputation as an environmentally conscious nation, the nation is likewise concentrating on producing textiles in a sustainable manner.

4.United States: Although the scale is usually smaller than in nations like China and Austria, there are several lyocell production facilities in the United States. Some businesses, like Lyocell, concentrate on producing sustainable and specialized textiles.

5.Southeast Asian nations like as Indonesia, Thailand, and Vietnam also produce lyocell, frequently meeting the needs of both domestic and international export markets.

Cellulose (usually from wood pulp) is dissolved in a non-toxic solvent before being spun into fibers to create Lyocell. Due to its closed-loop method that recycles solvents and water, the manufacture is renowned for being more ecologically friendly than other fabrics.

How Much Does Lyocell Fabric Cost?

The price of lyocell fabric can vary significantly depending on a number of factors:

1.Quality and Brand: Depending on factors like production processes, reputation, and quality, different manufacturers and brands may charge different costs. Because of their sustainability methods, well-known companies like TENCEL™ frequently fetch premium pricing.

2.Fabric Type: The pricing may vary depending on the type of Lyocell fabric (such as satin, plain weave, or blends with other fibers). The cost of specialty fabrics with extra features may vary.

3.Order Volume: Generally speaking, buying in bulk lowers prices per yard. Discounts for bigger volumes are frequently offered by manufacturers or wholesalers.

4.Sourcing: Costs may vary depending on where the fabric is made. The cost of fabrics originating from areas renowned for producing high-quality textiles can differ.

5.Market factors: Variations in demand and worldwide supply networks may have an effect on prices. For the most precise information, it is helpful to look at the state of the market right now.

Key Benefits of Lyocell Fabric

Why is lyocell fabric such a popular option for environmentally aware customers and brands? The following are some of the main advantages that make this material unique:

Softness and Comfort: Silk is often compared to lyocell because of its smoothness and richness. Because it’s gentle on the skin, lyocell is a good choice for clothing and people with sensitive skin.

Dissolving the Pulp: An organic solution that is safe to use is used to dissolve the wood pulp. This is a crucial phase in the closed-loop process which allows lyocell manufacturing to be less harmful to the environment than traditional methods such as those applied to silk.

Spinning the Fibers: The final mixture is then forced through spinning wheels to produce lyocell fibers with a fine texture. Before being turned into yarn, these fibers are cleaned and dried.

Creating the Fabric: Lyocell yarn is woven or woven into fabric. This creates a smooth, durable, and customizable material. Suitable for use in clothing. home textile and other uses.

The higher-quality fabric created by this method has become known for its strength, softness, and ability to drain away moisture. It is also less harmful to the environment.

Lyocell vs. Other Fabrics: How Does It Compare?

When it comes to choosing the right fabric, it’s important to understand how lyocell stacks up against other materials like cotton, viscose, and tencel. Let’s take a closer look at how these fabrics compare:

Lyocell vs. Cotton

Lyocell and cotton are often compared because they are both breathable and natural. However, there are some key differences:

Sustainability: While cotton is a natural fiber, it requires significant amounts of water and pesticides to grow. In contrast, lyocell is produced using a closed-loop process that’s more water-efficient.

Texture: Lyocell has a smoother texture than cotton, which can feel rougher in comparison. This makes lyocell a better choice for those looking for a silk-like softness.

Durability: Both fabrics are strong, but lyocell is less prone to shrinking and wrinkling, making it easier to care for.

Lyocell vs. Viscose

Viscose is another fabric that’s similar to lyocell, as both are made from wood pulp. However, there are differences in their production and environmental impact:

Production Process: The process for making viscose involves harmful chemicals that can be damaging to the environment if not properly managed. Lyocell, on the other hand, uses a non-toxic solvent and a closed-loop system.

Eco-Friendliness: Due to its closed-loop production, lyocell is considered a more sustainable option compared to viscose.

Feel and Performance: While both fabrics are soft and drapey, lyocell is generally more durable and moisture-wicking than viscose.

Lyocell vs. Tencel

Tencel is actually a brand name for a type of lyocell produced by the Austrian company Lenzing. So, when people ask, what is tencel lyocell? The answer is that it’s a high-quality form of lyocell that meets strict environmental standards.

Quality: Tencel lyocell fabric is known for its consistent quality and superior softness, making it a premium choice for many brands.

Brand Recognition: The Tencel™ brand is well-recognized, which can add value for brands looking to market their products as using a trusted sustainable material.

Conclusion: Why Lyocell is Worth Considering

Lyocell provides an opportunity to make beautiful, high-quality items with a little impact on the environment in a world when sustainability is more crucial than ever. Because of its softness, toughness, and environmental friendliness, it stands out above other options for customers and companies.

This adaptable fabric can help, whether you’re a designer seeking for an environmentally friendly replacement for cotton and silk or a customer looking for apparel made of lyocell that feels as wonderful as it looks. So why not investigate lyocell’s potential and see how it may improve your wardrobe while promoting environmental sustainability?

Adopting lyocell is more than just selecting a fabric; it signifies a dedication to better materials, a more salubrious environment, and an era when sustainability and fashion combine seamlessly.