Artificial intelligence in manufacturing is transforming production lines. But how can AI optimize efficiency, reduce waste, and improve sustainability? Or Have you ever wondered how factories of the future will operate? What if machines could predict their own failures or reduce energy consumption automatically?

By 2025, AI will revolutionize the industry, making it smarter, faster, and greener.

Platforms like Maker’s Row are already leveraging sustainable manufacturing practices to reduce waste and improve efficiency. From predictive maintenance techniques to additive manufacturing innovations, the future is here.

Artificial intelligence in manufacturing is transforming production lines. But how can AI optimize efficiency, reduce waste, and improve sustainability? This blog explores the top AI trends in manufacturing and how they are shaping the future.

How AI Transforms Manufacturing

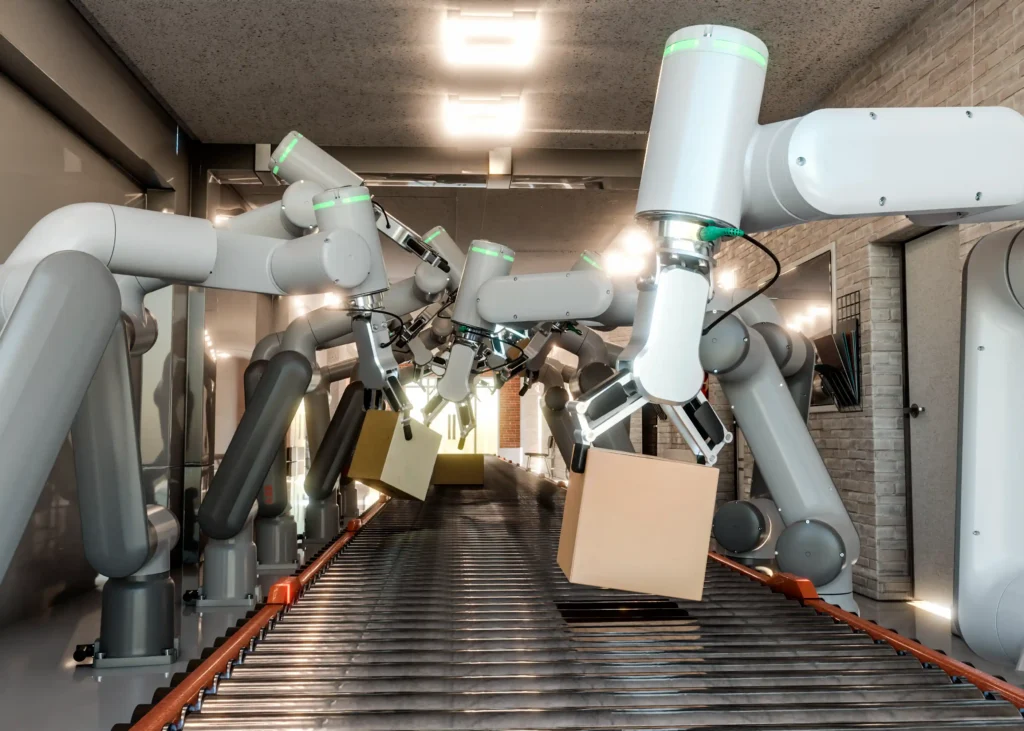

Artificial intelligence in manufacturing is reshaping production processes through automation, real-time monitoring, and data-driven decision-making. AI robots accelerate production speed and accuracy and reduce human errors. Studies show that AI-driven predictive maintenance reduces downtime by 50% and cuts costs by 30%. Companies like Amazon and Siemens integrate AI to streamline supply chains and production.

Predictive maintenance makes sure that machines work efficiently and prevents unwanted breakdowns. AI-based quality control checks for defects much more accurately, ensuring good product consistency. AI is also used in supply chain management by optimizing logistics and predicting demand. With the rise of sustainable manufacturing, AI also helps reduce waste and energy use, thus promoting sustainability. With the ability to analyze large datasets, AI allows manufacturers to make & evolve decisions rapidly and smartly, thereby improving efficiency and profitability. Moreover, firms leveraging AI could achieve higher productivity, lower costs, and a sustainable approach toward their future.

How Maker’s Row Helps in AI Manufacturing

Maker’s Row connects businesses with AI-powered manufacturers. This platform eases the search for suitable manufacturing partners. Need sustainable manufacturing solutions, smart manufacturing technologies, or help bringing product AI-driven innovations? Maker’s Row allows businesses to access all of the above easily.

Key Benefits of Maker’s Row:

- Easy access to AI-driven manufacturers

- Streamlined product development

- Support for sustainable and additive manufacturing innovations

Any company that chooses to pursue AI would benefit from Maker’s Row for its 2025 market competitiveness.

5 Key Trends in Artificial Intelligence for Manufacturing in 2025

1. Sustainable Manufacturing Practices with AI

Sustainable manufacturing practices are gaining traction. AI assists in reducing waste, optimizing energy usage, and minimizing carbon footprints. Companies use AI to monitor sustainability metrics and improve them.

Key Benefits:

- Lower energy consumption

- Reduced material waste

- Improved supply chain transparency

Example: Tesla’s AI-Driven Sustainability

Tesla uses AI to optimize battery production. This reduces waste and enhances efficiency.

2. Predictive Maintenance Techniques

Predictive maintenance techniques prevent unexpected breakdowns. AI-powered sensors analyze machine health in real time. Manufacturers save costs and improve productivity.

Statistics:

- Predictive maintenance reduces downtime by 30-50%.

- It cuts maintenance costs by 20-30%.

| Benefit | Impact |

| Less Downtime | 30-50% Reduction |

| Cost Savings | 20-30% Lower Costs |

Example: General Electric’s AI Maintenance System

GE’s AI-driven maintenance predicts failures before they happen. This keeps machines running efficiently.

3. Smart Manufacturing Technologies

Smart manufacturing technologies integrate AI, IoT, and automation. AI-powered robots streamline production lines. Real-time analytics improve decision-making.

Key Features:

- AI-driven robots enhance efficiency.

- IoT sensors provide real-time monitoring.

- AI-driven quality control minimizes defects

Example: Siemens’ AI-Integrated Factories

Siemens employs AI to automate production. Their smart factories boost efficiency and reduce errors.

4. Additive Manufacturing Innovations

AI has a positive impact on innovations in additive manufacturing such as 3D printing. AI helps with optimizing designs, as well as minimizing the amount of materials needed. This boosts the manufacturer’s savings as well as product quality.

Advantages:

- Prototyping is quicker

- Less is spent on materials

- Improved design precision

Example: BMW 3D Printing Adds AI For Better Results

BMW incorporates AI to improve the outcome of additive manufacturing. They have an automated system that incorporates AI to enhance the level of accuracy of design.

5. AI-Driven Supply Chain Optimization

AI improves the supply chain as well. Machine learning assists with optimizing demand and even logistics, resulting in less waste and faster delivery.

Benefits:

- Fulfillment of demand is more precise

- Operational expenses are less

- Better organized transportation

Example: Amazon’s AI-Powered Logistics

Using AI in logistics and the supply chain reduces delays in deliveries. Machine learning improves how the inventory is controlled.

Conclusion

The use of artificial intelligence in manufacturing transforms the industry. Many constructs such as maintenance and the process of manufacturing, as well as predictive techniques are advanced for optimal results. It is important to welcome AI for companies in 2025.

Looking for more insights? Check these out!