Quality control is an important aspect in almost every industry. It is essential to maintain the quality of production and services provided. The jewelry industry is known for its attention to detail and to deliver flawless products. Quality control is a critical factor in jewelry manufacturing, as it is essential to meet the expectations of consumers. Jewelry factory quality control procedures not only prevent defects and errors but also help to build trust

In jewelry manufacturing, quality control should be maintained according to jewelry production standards. From selection of raw materials like gemstones or metals to final inspection of jewelry pieces. There are various key components for an effective quality control system. If attained and practices lead to achieving superior quality in jewelry manufacturing.

Here are some best practices that help to achieve quality control in jewelry manufacturing

image credit: pinterest

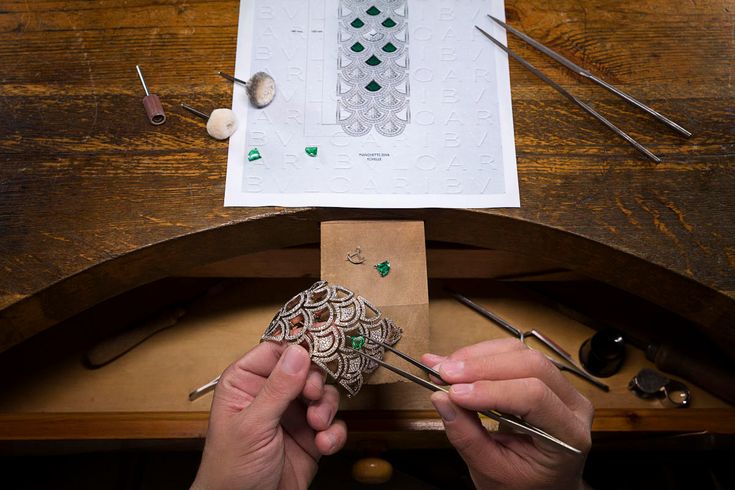

1. Design And Prototype Review

To maintain jewelry factory quality control procedures, before jewelry production begins, it is essential for factories to thoroughly assess the jewelry design. They need to check the design for its functionality. It also needs to check the sharp edges of jewelry pieces and other quality considerations. They can also create prototypes to test the design of jewelry pieces and their functionality.

It is important to review the prototypes carefully and make adjustments if necessary. This prototype should be informed to the quality control team too. So that they can check it properly before moving towards the next step, which is mass production of jewelry.

2. Material Inspection

Manufacturers should ensure that the metals, gemstones, and other materials sourced for jewelry manufacturing meet the required jewelry production standards. Jewelry factory quality control procedures also state how they should verify the authenticity of gemstones and precious metals through the certification from suppliers. They can also check the purity and alloy composition of the metals.

If materials are sourced in bulk, manufacturers can conduct random sampling tests. This helps to check the consistency and quality of raw materials. It is important to test the purity and reliability of gemstones and metals before actual production begins.

image credit: pinterest

3. In Process Inspection

To achieve jewelry factory quality control procedures, factories should perform regular visual inspections. This helps to find any visual defects in jewelry production pieces. It can be defects such as scratches or wrong gemstone placement or irregularities in plating. They should check the size, weight, and proportion of each jewelry piece using micrometres and other devices.

This ensures consistency about the quality as well as quantity of the produced jewelry. There is also a step where they need to check and inspect about the cracks, porosity, or other defects. If they avoid these issues, it can weaken the quality of jewelry and compromise the quality and integrity of jewelry.

4. Finishing And Polishing

Another jewelry factory quality control procedure includes inspecting all surfaces of jewelry pieces. It should be done by manufacturers for checking smoothness. It also helps to check the polishing and absence of any other requirements. The jewelry pieces should have a clean, polished finish without any scratches or blemishes. It is also an integral part of inspection to check the plating and uniformity. It is required for plated jewelry, especially. This helps to meet the jewelry production standards.

image credit: pinterest

5. Testing For Durability

Manufacturers should conduct and perform tests for durability according to jewelry factory quality control procedures. It includes checking the strength and hardness of jewelry pieces, such as scratch tests for metals. The jewelry should be able to withstand wear and tear without compromising the appearance of jewelry pieces or function. They should also check for metals if they are non-allergic or reactive on skin. Especially when worn by consumers for a long time. This helps to take a preventive measure before selling it in the market.

6. Final Inspection And Quality Assurance

There should be detailed final inspection and checking procedures before shipping and packaging of the product according to jewelry factory quality control procedures. Each jewelry piece should undergo a final inspection to ensure that it meets design specifications and standards of quality, along with consumer expectations. They can also provide necessary certifications like metal purity and gemstone authenticity in the packed pieces.

It helps to create transparency and clarity between buyer and seller. They can also maintain records of inspection, telling results and corrective actions for future and maintaining jewelry production standards.

image credit: pinterest

7. Technology And Automation

For better maintenance of jewelry factory quality control procedures, factories can implement tools like 3D printing or laser engraving for better quality processes. It can also use automated inspection systems for enhanced precision and efficiency in both design and jewelry manufacturing. They can also use software for tracking each piece of jewelry produced through every step of production. It ensures that nothing is avoided or missed in the quality check process.

8. Feedback Loop And Continuous Improvement

According to jewelry factory quality control procedures, manufacturers can regularly collect and analyze feedback from consumers and retailers. This helps to identify any quality issues that are recurring. This feedback collected or received is valuable resources for improvement in jewelry manufacturing. It can be used to improve designs, production techniques, and control quality procedures. Continuous improvement helps to prevent errors and refine quality in jewelry production standards.

image credit: pinterest

Finding a quality jewelry manufacturer? Connect through Maker’s Row

It is important to find the best partners that can help in achieving best practices for jewelry manufacturing and production. Well, an easy route for finding a reliable partner is Maker’s Row. It is an online platform that not only connects brands and manufacturers based in the U.S. and from other countries but also helps finding manufacturers, including from the jewelry industry too. Here’s how Maker’s Row assists:

→ Maker’s Row offers an experienced list of factories and manufacturers that specialize in various aspects of jewelry production. So if a factory has signed up and is listed on the platform, it helps to connect with jewelry brands and businesses looking for manufacturers who are skilled to execute high-quality work and jewelry production standards.

→ All the factory manufacturers listed on the platform can showcase their services, custom jewelry designs, and gemstone certifications through their profiles. This transparency helps to connect with brands that are searching for best practices in jewelry manufacturing.

→ Maker’s Row allows brands and startups to directly work with factories that understand and prioritize quality control. Thus, brands get the required jewelry production standards for their jewelry line.

→ Jewelry manufacturers can get access to connect with the best quality suppliers through the Maker’s Row platform, which thus helps in high-quality production, helping brands to collaborate with factories that achieve jewelry factory quality control procedures.

Maker’s Row as a platform helps to connect jewelry brands and factories with industry professionals to network and learn about industry trends, which helps to stay ahead of the competition and adapt best practices.

image credit: pinterest

Conclusion

Hence, by implementing jewelry factory quality control procedures in the jewelry manufacturing process, it can help to consistently improve and provide quality jewelry pieces. And sourcing quality materials from supplies also helps. This helps in achieving customer expectations and jewelry production standards while creating a loyal customer base. Meeting industry standards helps factories to mark their presence in the market through quality production. It also helps to minimize returns and dissatisfaction, which leads to positive word of mouth and helps in getting new clients.

You Can Also Read..