Leveraging jewelry manufacturing technology to improve manufacturing processes is key to driving innovation and efficient production in modern industries. It comes across as a revolution in the industry. As every sector is facing competition along with demand for quality products and solutions to reduce costs, it is an idle approach to adapt advanced technologies. Leveraging technology to improve jewelry manufacturing provides great precision, efficiency, and creativity.

There are various advanced technologies introduced in the jewelry industry that enhance design and jewelry production capabilities. It not only allows intricate designs and reduces waste but also helps in maintaining high standards of craftsmanship. It also meets the growing expectations of modern consumers. As jewelry making is known for traditional methods, with modern jewelry manufacturing technology, it can enhance the jewelry manufacturing process.

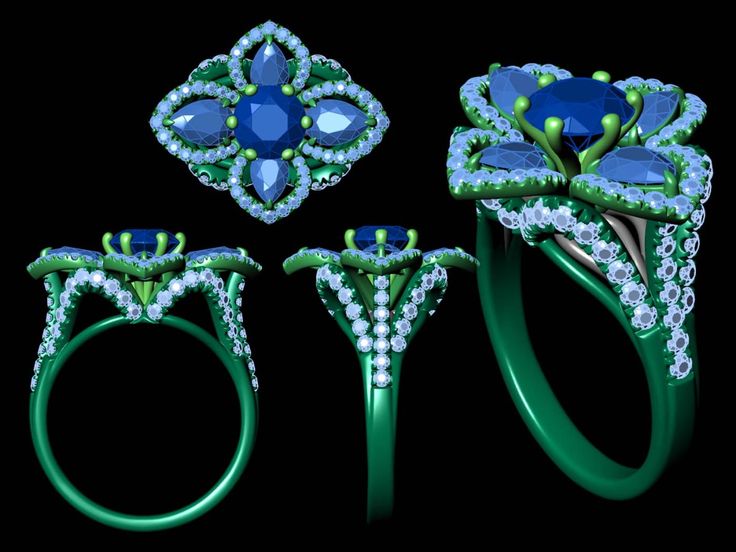

Benefits of using technology in jewelry manufacturing

image credit: pinterest

→ Speed Efficiency

In technology, process automation and digital tools reduce production time and even labor costs. It makes it much easier for manufacturers to produce jewelry pieces efficiently and without much effort. It helps to increase the speed of production and meet deadlines before or on time. The use of jewelry manufacturing technology helps in managing and producing large quantities of jewelry pieces efficiently.

→ Precision And Quality

Advanced jewelry manufacturing technology enhances the level of minute details and precision. It also increases the accuracy of designs. This precision is often not attained with manual methods. Process automation helps to improve the overall quality of finished products. While also reducing defects and errors in jewelry manufacturing.

image credit: pinterest

→ Sustainability

With the use of jewelry manufacturing technology, it contributes to sustainability by reducing waste and energy consumption. As sustainable and ethical practices are on the rise in the jewelry industry too, it aligns with the growing consumer demand for environmentally friendly products. Use of process automation also gives a different presence in the jewelry industry. Thus, it makes the inclusion of technology successful in jewelry manufacturing.

→ Cost Reduction

By minimizing the waste in the production process through jewelry manufacturing technology and optimized processes, it also helps in labour cost reduction while maintaining the quality. The saved expenses can be used by jewelry manufacturers in the future for installing and updating new technologies or even in the maintenance of technology machines used for jewelry manufacturing.

Key technologies in jewelry manufacturing that improve the processes

image credit: pinterest

1. 3D Printing

3D printing is becoming popular day by day, even in the jewelry manufacturing technology. It helps in rapid prototyping as compared to the traditional methods of creating samples. This technology allows jewelry manufacturers to create highly complex, customized designs that are difficult to achieve with traditional methods, along with being less time-consuming. It also reduces the material waste that usually gets created by building sample objects in layers. It speeds up because of the process automation and enhances the production process and development.

2. Laser Cutting And Engraving

Jewelry manufacturing technology like laser cutting is used for cutting and creating intricate patterns and designs into metals, stones, and other materials. Laser technology offers high precision that traditional and manual methods cannot match. It allows for faster processing of jewelry production of detailed patterns on jewelry pieces. It is especially useful in creating complex designs effectively and in adding customized touches to jewelry pieces like initials or any words.

image credit: pinterest

3. Automation And Robotics

In today’s time, process automation is playing a large role in the jewelry industry. Be it a particular task like polishing, cutting, or stonesetting. Robots can work accurately and consistently without making mistakes and errors. This jewelry manufacturing technology helps the overall performance of jewelry production efficiently and reduces human errors too. For example, setting a diamond in place of emeralds. The automated system helps in growing the jewelry production without ignoring quality.

4. Virtual And Augmented Reality

Nowadays, jewelry manufacturing technology like virtual and augmented reality in jewelry design is used for providing a better customer experience. With augmented reality, customers can visualize how particular pieces of jewelry will look on them before purchasing. This helps in enhancing the shopping experience. Even for designers, virtual reality can provide an experimental environment where they can try and test various design variations before finalizing them for jewelry manufacturing.

image credit: pinterest

5. Computer-Aided Design And Artificial Intelligence

CAD software has revolutionized jewelry design by allowing designers to create intricate, detailed models digitally. This jewelry manufacturing technology helps in controlling the overall design elements and helps in making adjustments easily. With process automation, it simplifies the process of designing and makes designers easily communicate with manufacturers about designs before the production process begins.

Artificial intelligence is an effective solution that helps in predicting future trends and understanding consumer preferences regarding jewelry. AI also supports predictive maintenance and reduces issues even before they occur. It leads to efficient operation and improved quality control in jewelry manufacturing.

How does Maker’s Row help to connect with technologically advanced jewelry manufacturers?

Maker’s Row is an online platform that connects and collaborates businesses with brands and manufacturers based in the US and other countries around the world too. It helps brands and manufacturers from various industries, including the jewelry industry. It helps in streamlining the jewelry manufacturing process and also finding jewelry supplies. Here’s how it helps:

→ When a manufacturer or factory is profiled on the Maker’s Row platform, it helps to connect brands and businesses with them through their efficiently curated list of manufacturers. It features a wide range of manufacturers specializing in various aspects of jewelry production, from 3D printing to custom designs and finishing of jewelry pieces that helps in process automation.

This helps brands to find and collaborate with factories and manufacturers that are technologically advanced. And also view their profile to learn about their past work and experiences.

→ The platform allows direct communication between designers and manufacturers for a clear discussion about technology needs such as automation processes, laser engraving, or 3D printing. This ensures to collaborate with manufacturers that can deliver according to requirements.

→ Maker’s Row also provides valuable information and guidance with the help of industry experts that helps guide and make them understand modern manufacturing technologies and process automation too and this helps to find the right factory manufacturing partner who brings the designs turned into reality.

image credit: pinterest

Conclusion

Thus, it can be said that integration of jewelry manufacturing technology into the manufacturing process is helping to reshape the jewelry industry. As it offers more efficient ways to manufacture jewelry pieces. It also helps in attaining sustainability and personalized ways of creating the jewelry. By adapting these process automation techniques, both manufacturers and brands can earn the perks. As it helps in enhancing the jewelry manufacturing capabilities, meeting the evolving needs and demands of the consumers, and staying competitive and relevant in the digital world.

You Can Also Read..